From Bamboo to Paper

How Bamboo Paper is Made

Did you also see the episode of Keuringsdienst van Waarde? We certainly did. The episode provided a lot of information about using bamboo for various products, some may already be familiar with it and others not.

There has been much discussion about the chemical (viscose) process used to make textiles from bamboo. About the chemicals involved, and how sustainable the further production process of this actually is.

The main difference between using bamboo for clothing and using bamboo for paper is that making bamboo usable for sewing clothing requires a chemical viscose process. The production process from bamboo to toilet paper does not involve a viscose process, which makes it a lot less harmful. However, we would also like to give you more clarity about our (social) enterprise and what we are doing to optimize our processes. Because: despite the fact that our products are currently the most (socially) sustainable alternative in the toilet paper industry, we can always be even more sustainable.

As you may know, our bamboo toilet paper is currently produced in a B Corp certified factory in Europe. More about that in a moment…

First, some more special news: next year we will be producing our bamboo toilet paper with our own bamboo from Ghana! How cool is that? This way, we have influence on all processes in our chain, from the strong bamboo plants in Ghana to the soft bamboo toilet roll that is available in our shop, and everything in between. The best side effect of this? We provide employment and a fair income for our bamboo farmers, and we can start researching the use of enzymes instead of chemicals in the production process in collaboration with experts.

Watch a short video here to learn more.

What does a B Corp factory in Europe mean and how do we produce our bamboo?

The B Corp factory we partner with to produce our bamboo toilet rolls is a pioneer in carbon neutral paper production . How did they achieve that goal?

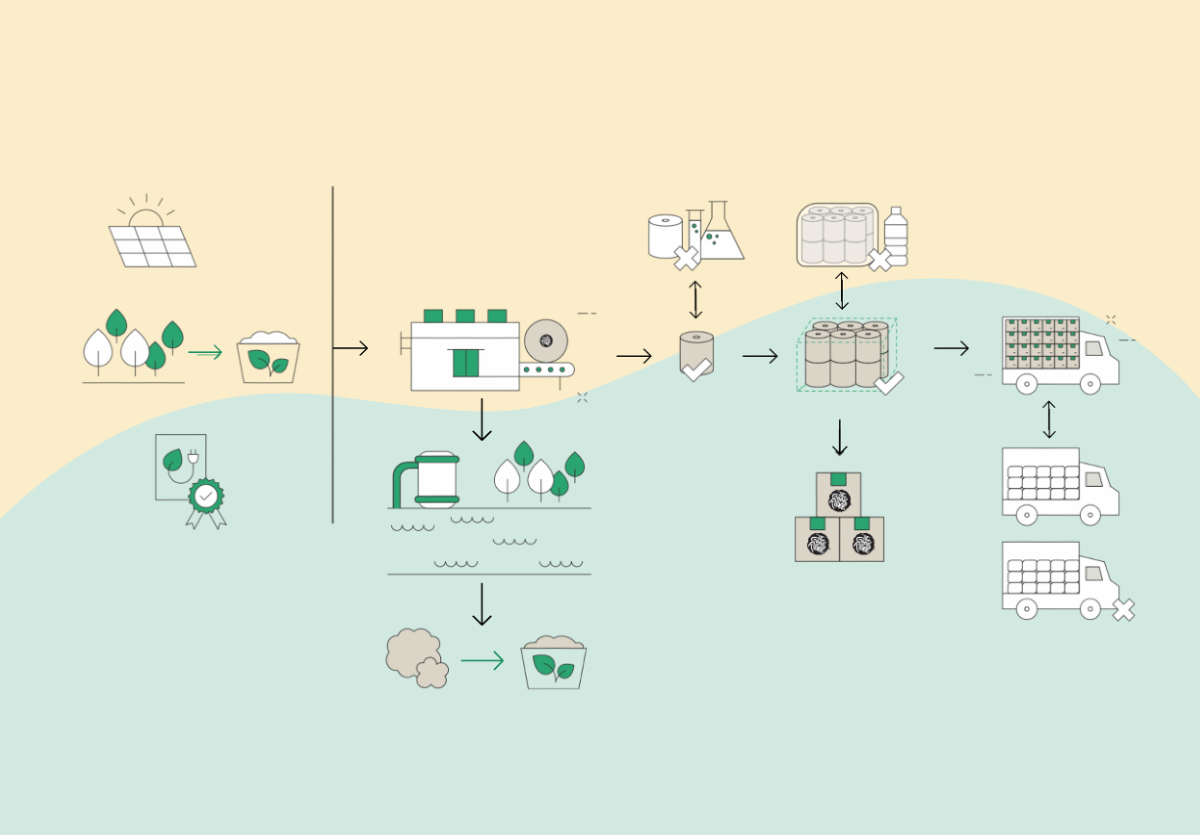

Papermaking is a process that requires enormous amounts of energy. Our partner mill uses their own solar power plant , with over 8,000 solar panels, and a biomass plant to generate steam, which is fed with residues from nearby forests . If more energy is needed, they buy it from suppliers with a 100% renewable certified origin .

Making paper also requires a lot of water. After use , the water is restored to the same state as it was originally used thanks to the water purification plant and returned to the river. The residues that arise during the water purification process are later reused to generate electricity . In this way, they work towards a zero-waste horizon.

The use of bleach and other unnecessary chemicals is also avoided. Instead, the products are made with unbleached fibers .

Finally, in our bamboo toilet paper process, we have replaced all plastic packaging with cardboard . Not only is it recycled and recyclable, it is also stackable . This allows for major logistical optimization, which means fewer trucks need to be deployed. Fewer trucks = less emissions!

Because: our goal is to make the world's most (socially) sustainable toilet paper . Below you can see the entire process in a diagram.

In addition, the bamboo products have been awarded several certificates, including:

FSC Mix

EcoVadis Gold (maximum score in CSR)

Produced in a B Corp plant

Ecolabel

ISEGA – food contact compliant (for kitchen rolls)

REACH compliant

Chlorine free

Back to the Inspection Service of Value episode…

As highlighted in the episode, currently all bamboo (toilet paper) worldwide is produced in China.

The pulp that is used as described in the above process comes from China. However, in order to make the most (socially) sustainable choices within the existing possibilities regarding bamboo, we have chosen to only get semi-finished products from China. This has 2 advantages:

-

Instead of cargo ships full of boxes of bamboo toilet rolls from China to Europe, only the dried bamboo pulp is shipped. This takes up much less space, which in turn results in less emissions. Already a step in the right direction if you ask us.

When the pulp arrives in Europe, the bamboo pulp is rigorously checked to see if it is in order and no harmful substances can be traced from the pulp. In order to be able to make our rolls, the bamboo pulp must meet an extensive list of quality and safety tests - which are carried out according to industry standards by external certification companies in an independent laboratory. They help us to declare, among other things, that the products do not contain any harmful chemicals.

Once the pulp has passed all the tests and is approved, it is processed into rolling paper and rolled into our double-thick rolls in a European B Corp factory.

Where other bamboo toilet roll sellers often export the entire bamboo roll from China, we have our rolls made in Europe. In this way, we can currently screen our chain from the pulp tests. Because we want to be 100% certain that we have the most (socially) sustainable toilet paper product in the world, we want to have a 100% transparent chain. As you may have read before, we are busy with this in Ghana. We hope to be able to make the Ghanaian bamboo rolls available to you as soon as possible! Then we will officially be the first in the world to make their paper with bamboo that does not come from China.

We do our stinking 💩 best to work with the most sustainable parties within all existing possibilities. Parties that have the right certificates, also in China. In addition, we are also proud owners of a B Corp certificate in the Netherlands. We are committed to becoming a step more sustainable every day.

Do you have any tips or feedback on how we could do this? We would love to hear from you! Send us an email at hello@thegoodroll.nl !

Keep rolling with us